Mines, quarries and underground workings in meshed networks

Our engineering and design department has a wide range of skills to accompany you and carry out ventilation studies for all types of work carried out in underground, closed or confined environments.

Identification of the current situation

During the realization of ventilation studies for mines, quarries and underground works in meshed networks, our engineering department first carries out audits, expertises and technical visits, allowing our engineers :

- Analysis of the current ventilation plan

- Analysis of the history of periodic measurements

- The recognition of the galleries and the specificities of the site

- Measurements of the main air flows and parameters

- Identification of the standards in force

- The drafting of an expert report highlighting the discrepancies and dimensioning the measurement campaign necessary to carry out a ventilation study, if necessary.

Realization of measurement campaigns

Before carrying out a study, it is necessary to know perfectly and in detail the architecture of the underground site and its functioning. For this, it is necessary to carry out an exhaustive measurement campaign to form the basis of our future modeling. This measurement campaign will be made up of the following points in particular:

At the end of this campaign, the operator will have a measurement report considered as the current image of his farm.

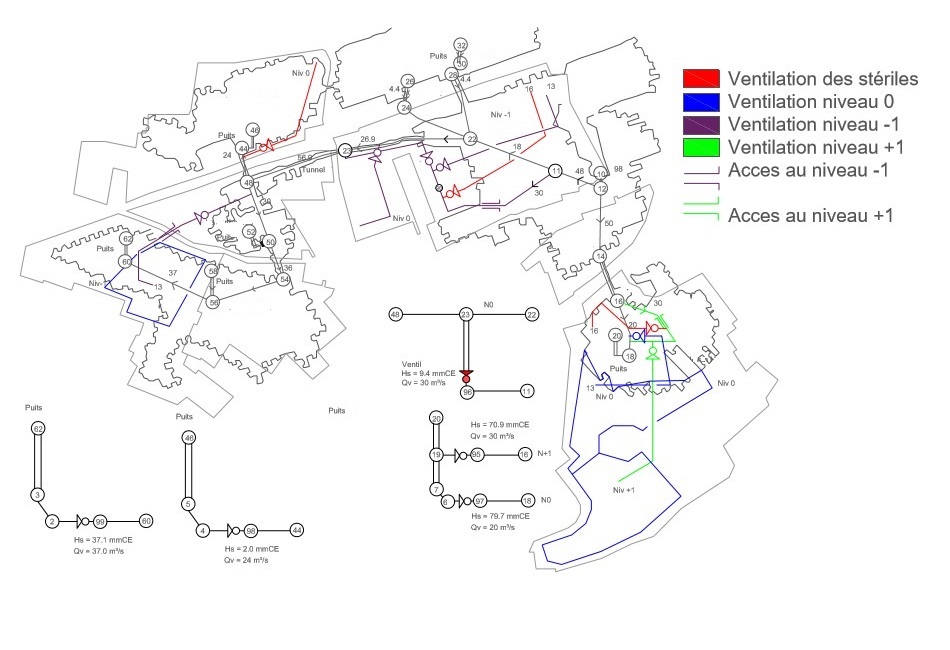

Numerical modeling of the site ventilation network using our AERO software suite

A ventilation study consists of a series of calculations to be performed on a numerical model allowing different simulations. This numerical model must be built and « tuned » to be a faithful representation of the operation at the time of the measurement campaign.

This faithful representation, also called « test problem », will be used as a basis for all future simulations.

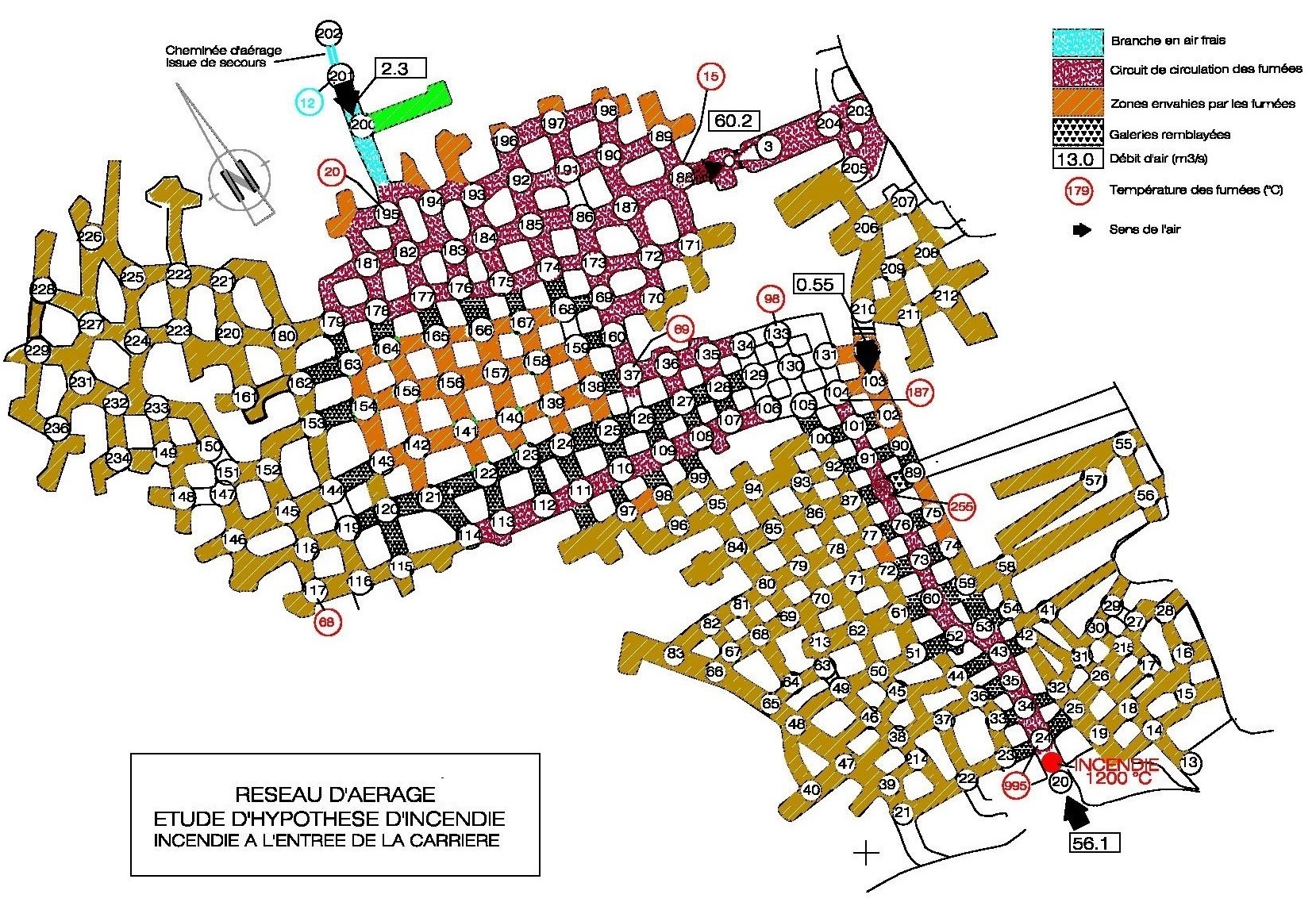

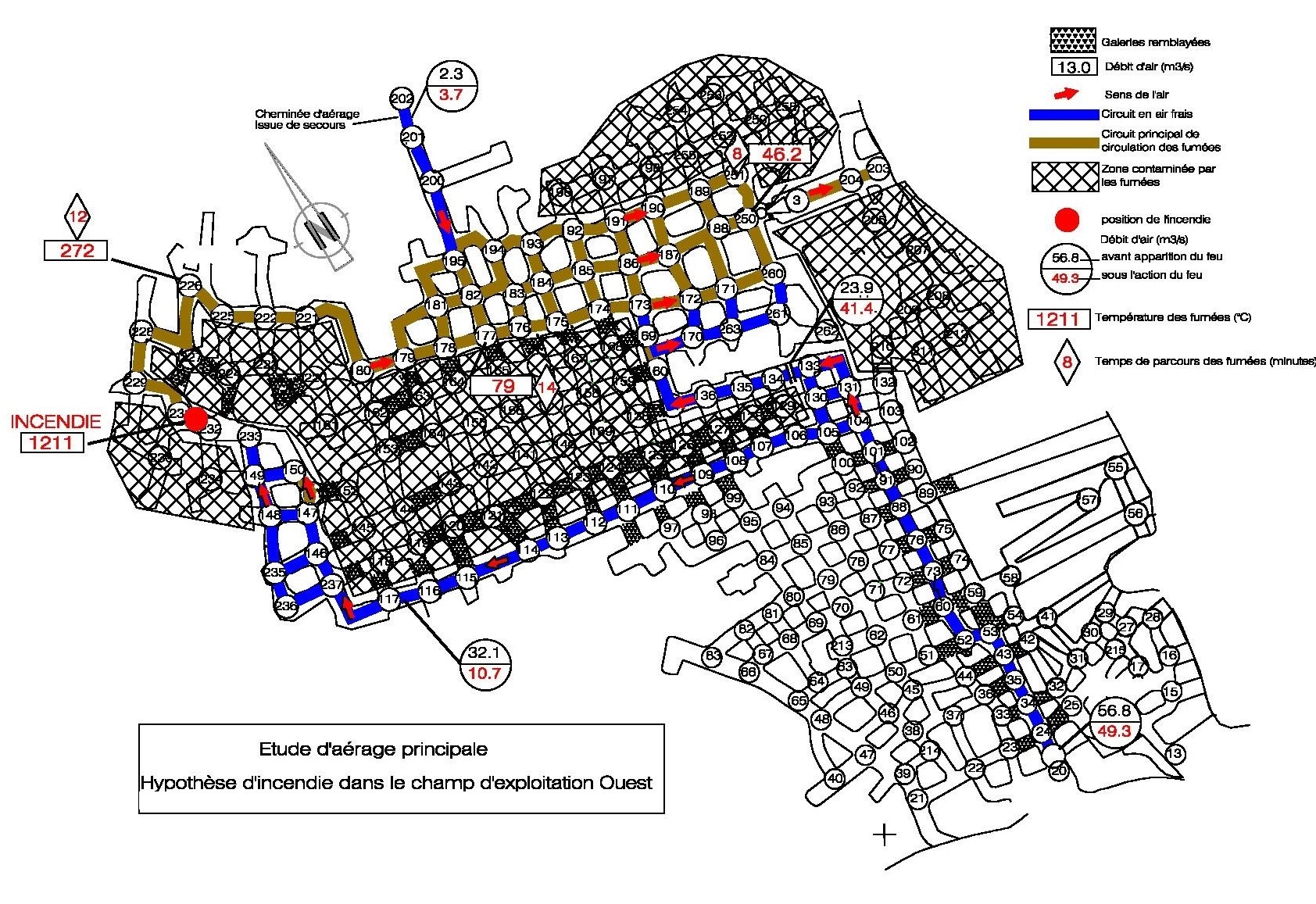

Simulation according to different scenarios:

According to the specifications, or the desired objective, we carry out, with the help of our modeling, all the simulations necessary to obtain results, such as for example :

Realization of periodic measurement campaigns and updating of the numerical model

Beyond the regulatory obligations and the recommendations of the prevention organizations, it is necessary to carry out periodic measurement campaigns made necessary by the evolution of the network and to detect anomalies if necessary.

- The ventilation measurement campaign to ensure compliance with the regulatory minimum flow rates and limit levels of harmful gases in the ventilation system and compliance with the ventilation studies carried out.

Measurements of the noxious gas content of diesel engine exhaust fumes every 250 hours of operation in accordance with the regulations to detect any pollution drift from each machine as quickly as possible.

Measurements of the exposure of workers to inhalable and alveolar dust.

Inventory of new excavations, dams, modifications to the ventilation network to update the digital model.

Updating of the regulatory ventilation file with a measurement report from our engineering office.

In addition to regulatory obligations and the recommendations of prevention organizations, it is necessary to carry out periodic measurement campaigns designed to monitor developments and detect any anomalies.

These periodic measurement campaigns complement the daily measurements carried out by the operation. The PVs and measurement reports carried out by our organization are authoritative vis-à-vis the labor inspectorate and any other regulatory body.