Underground civil works

Our engineering department has a wide range of skills to accompany you and carry out ventilation studies for all types of public works carried out in underground environments.

Whether it concerns shafts, tunnels, stations or any other underground work, our experts are at your disposal to assist you in your project.

Identification of the current situation

Underground public works are characterized by a complex phasing and a multidisciplinary approach to operations and stakeholders.

In order to advise you and carry out a ventilation study, it’s necessary that our engineers analyze your project in depth. Therfore this step includes in particular :

- An analysis of the project, the work plans, the phasing, the problem.

- The identification of the standards in force and the determination of the needs adapted to the constraints.

- A technical visit on site if necessary.

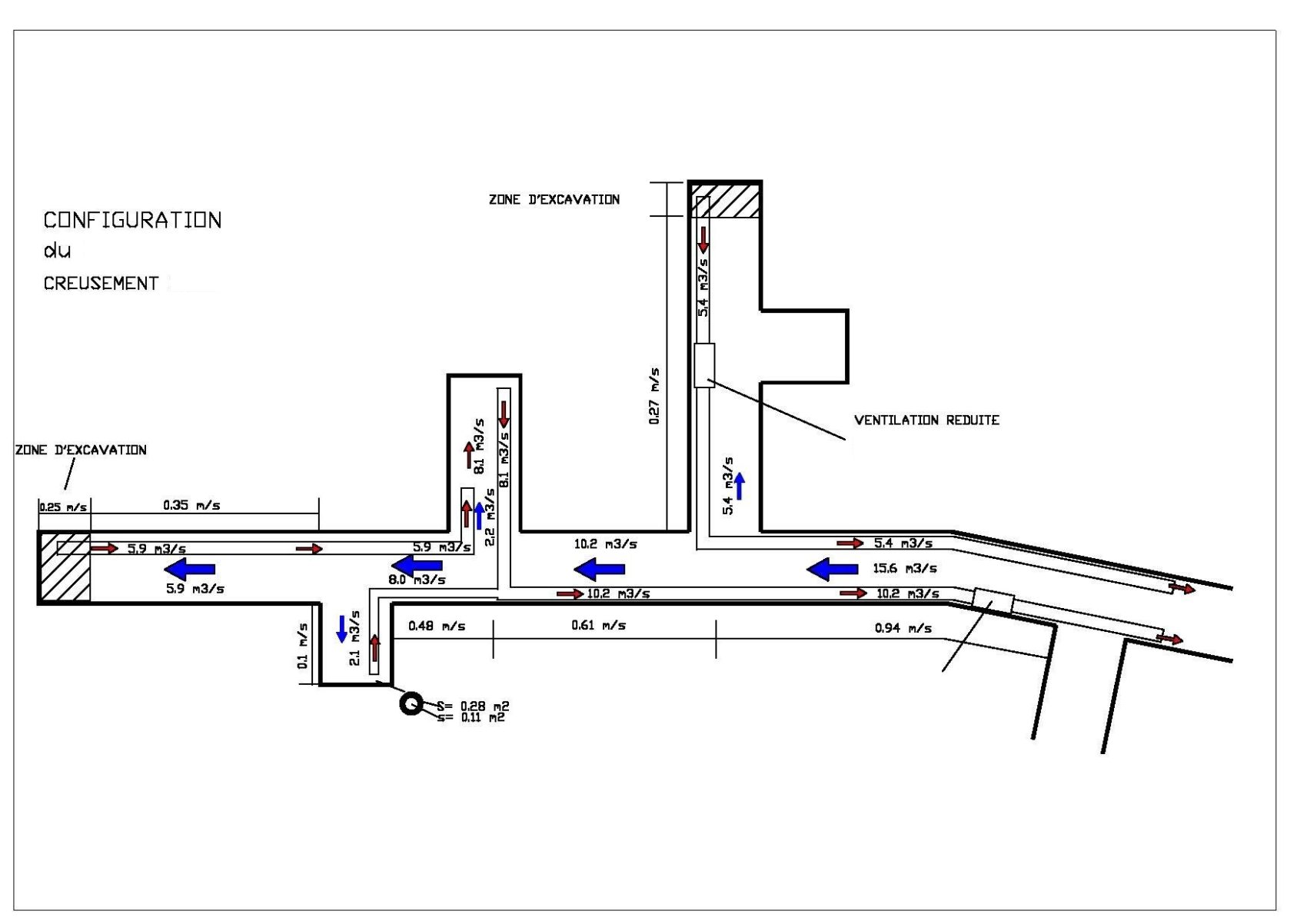

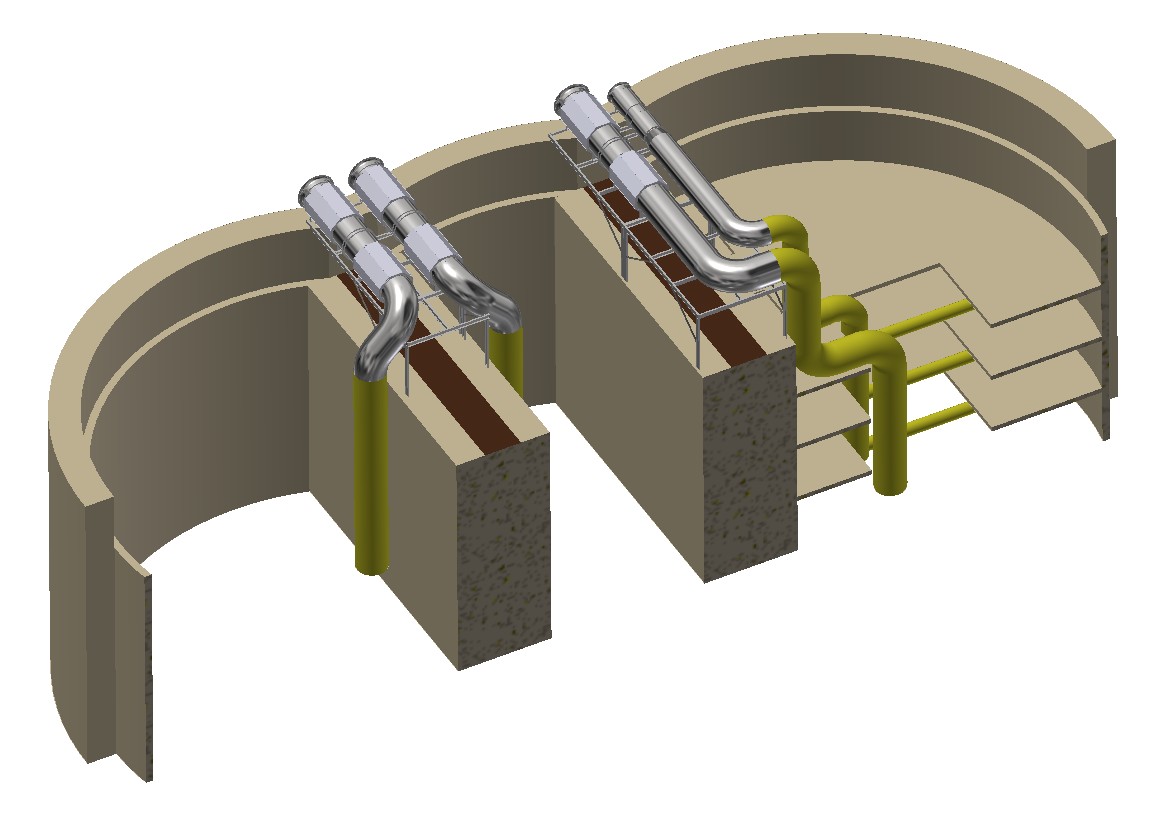

Determination of the ventilation concept

The whole objective is now to define a ventilation concept capable of responding to the different phases of the construction site. Therefore, the most economical and ecological ventilation concept should be defined by selecting high-performance fans, suitable duct diameters and materials. For example, an increase of a few millimetres in the diameter of the ducts will result in an electrical saving of several kilowatts.

For this purpose, it is necessary to carry out a ventilation study consisting of calculation notes and ventilation drawings/diagrams according to the following points :

Simulation and analysis of the consequences of a fire on the ventilation system

The analysis of the impact of a fire during excavation work is a fundamental element of worker safety. The whole issue is to evaluate the accessibility of escape routes from work areas to the outside. These calculations must be carried out taking into account a possible degradation of ventilation, as well as the following points:

We can in some cases perform hot smoke tests to demonstrate the impact of the presence/absence of ventilation, the rate of descent of the smoke ceiling, or any other phenomenon to show the consequences of a fire.

This physical simulation can also demonstrate the efficiency of a smoke extraction installation.

Sizing of air-conditioning systems for excavation sites

We have the necessary software and skills to dimension the refrigeration installations to be installed on ventilation lines for excavations or hot worksites. This study includes the following points in particular :

Realization of measurement campaigns

At the end of this campaign, the operator will have a measurement report considered as the current image of its site.

In some cases, these measurement campaigns can be carried out automatically thanks to the installation of a parameter monitoring system.

The monitoring system consists of the distribution on site of multiparametric measurement beacons which record in real time the contents of noxious gases, temperature and humidity, the rise of dust and fine particles, atmospheric pressure, as well as air speeds. This system called SENSOR’BOX fully meets regulatory expectations.