VENTILATION SYSTEMS FOR UNDERGROUND MINES AND QUARRIES

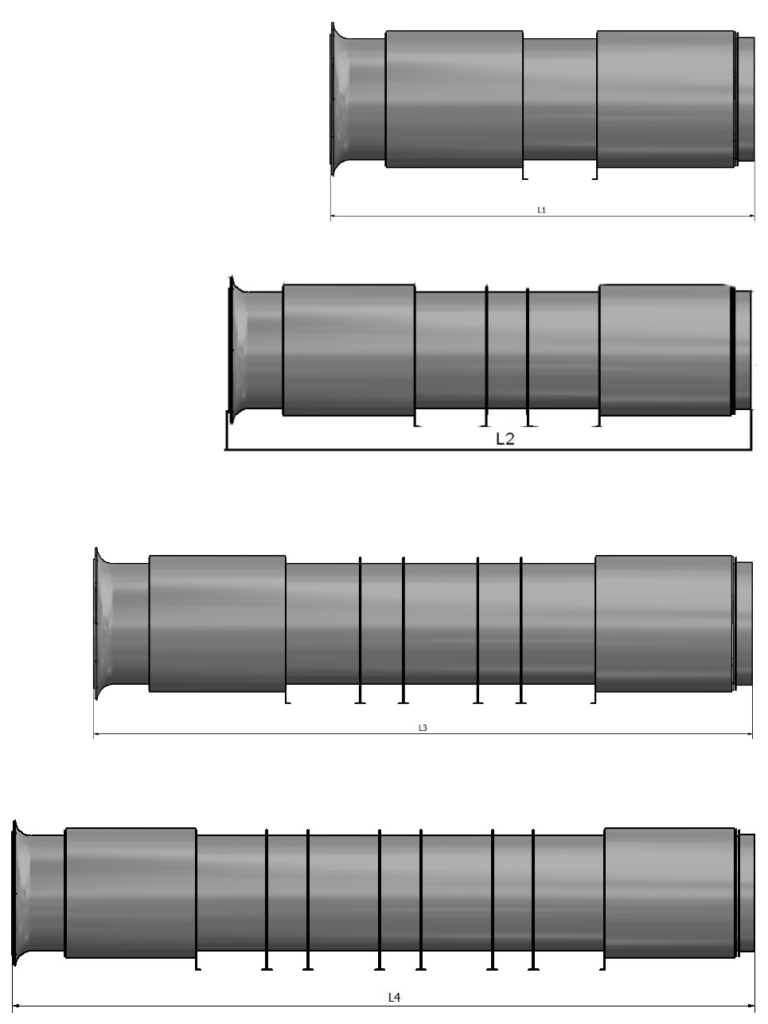

Various configurations

We are able to design fans ranging from single stage (1 stage) to multi-stage (up to 4 stages) adapted to the constraints and phasing of your site based on the following characteristics:

- Casing made of S235JR steel with galvanised or epoxy paint finish.

- The motors supplied have, depending on the case, a supply voltage of 230/400V or 400/690V (230V single phase/1000V or other on request).

- Our fans are equipped with support feet as standard, but can be optionally mounted on fixed or mobile chassis (wheels, sledge/skid, etc.) for ease of movement.

- The propellers are made of blades whose material varies according to the application propylene, glass-fibre reinforced propylene, aluminium, antistatic plastic. Thanks to our high quality materials and our design software, we can provide you with the propeller best suited to your constraints. Being at the forefront of propeller technology is part of our commitment.

Choice of equipment levels

Ventilation ducts and networks

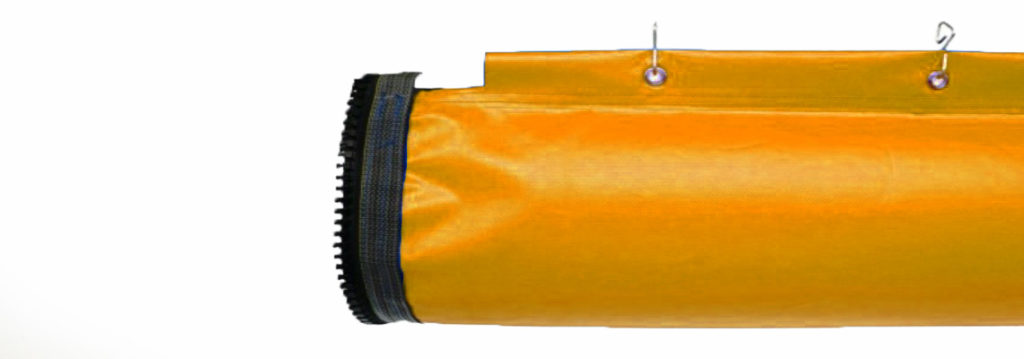

Flexible spiral ducts, more commonly known as « Spiragaines » are ducts that allow a fluid, in this case air, to circulate, which may be loaded with pollutants, dust or gas. They can be used for either blowing or suction (in overpressure or underpressure) and can be connected by different technologies (belts, straps, zip,…).

They are originally produced with 550g/m2 PVC, but can be produced with PVCs from 300 to 1000g/m2 on request and are packaged in sections of 5, 10, 15 or 20 metres.

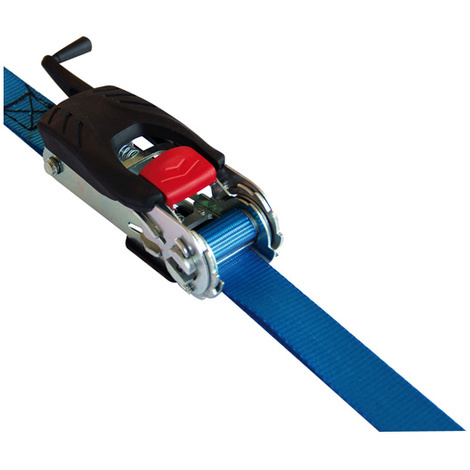

Types of duct connections

Ventilation walls

In addition to designing multi-stage fans, we are able to design customised ventilation solutions for your underground projects such as ventilation walls.