Industries and fluid transport networks

Our engineering office has a wide range of skills to support you and carry out studies for your fluid transport networks (air, water, gas, etc.). Whether it’s a collection network, pollutant suction or a distribution network, our company has different software to model complex fluid networks.

Identification of the current situation

During the realisation of ventilation studies for industries and fluid transport networks, our engineering department first carries out audits, expert appraisals and technical visits, allowing our engineers :

- The analysis of fluid transport network plans

- The recognition of the site

- Measurement of the main air flows

- The identification of the industrial process and the highlighting of the discrepancies

- The drafting of an expert’s report

Realization of measurement campaigns

Before carrying out a study, it is necessary to know perfectly and in detail the architecture of the fluid transport networks and its operation. For this, it is necessary to carry out an exhaustive measurement campaign intended to be the basis of our future modeling. This measurement campaign will be made up of the following points in particular:

At the end of this campaign, the industrial operator will have a measurement report considered as the current image of its site.

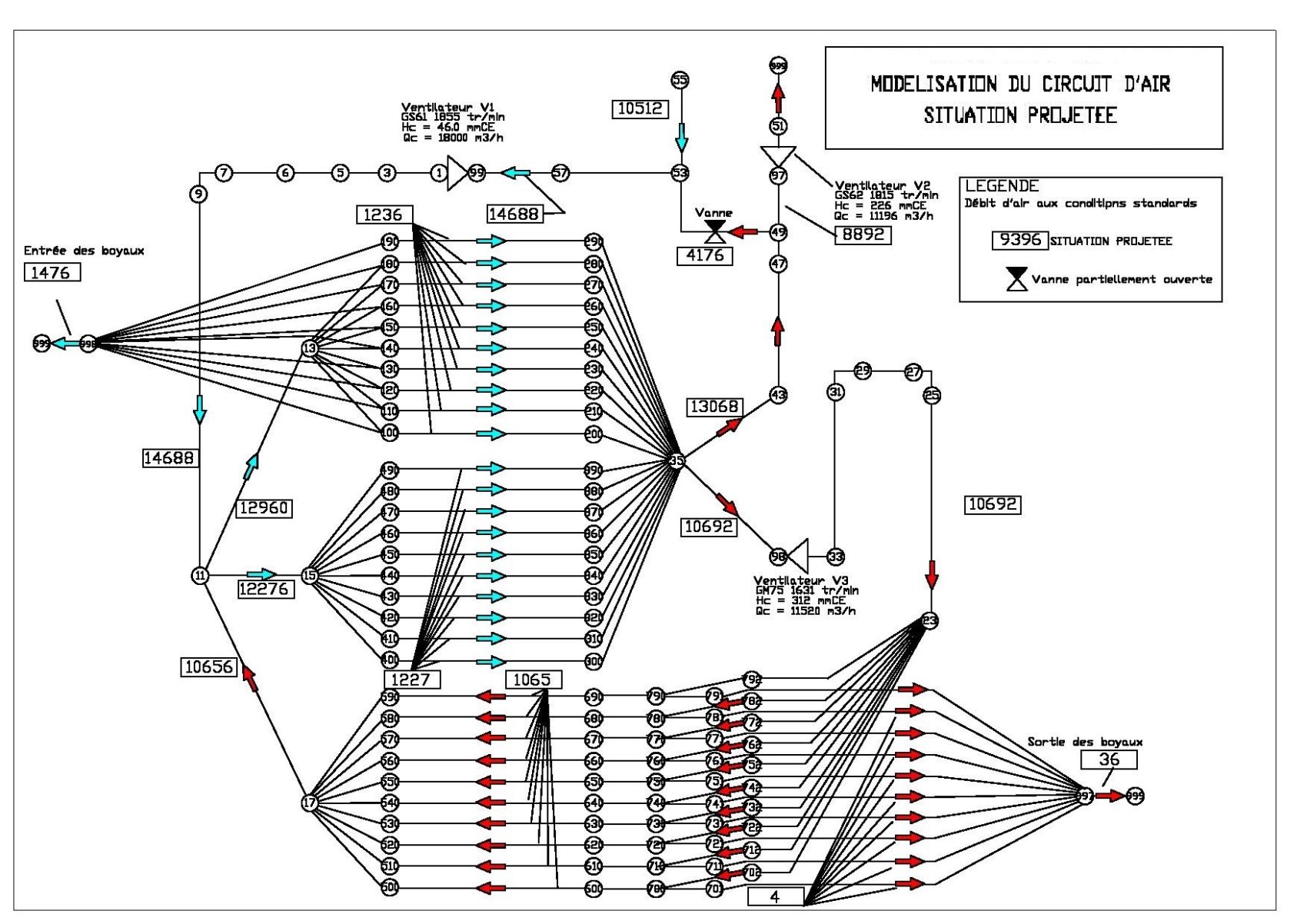

Numerical modeling of the site’s fluid network using our AERO software suite

A ventilation study consists of a series of calculations that must be performed on a numerical model allowing different simulations. This numerical model must be built and « tuned » to be a faithful representation of the fluid network at the time of the measurement campaign.

The results of the initial modelling must correspond to the situation of the measurement campaign. This model will be called test problem and will be used as a basis for all future calculations.

Simulation according to different scenarios:

According to the specifications, or the desired objective, we carry out with the help of our modeling all the simulations necessary to obtain results, such as for example :

- Adaptation or change of industrial process requiring a redefinition of the ventilation or pumping means.

- Addition of new production lines and impact on the facility in the short, medium and long term

- Energy and economic optimization