Explanation of the main (or primary) ventilation

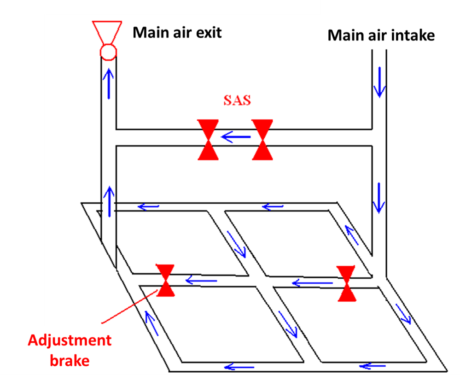

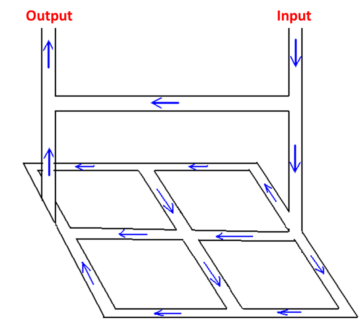

Main ventilation network

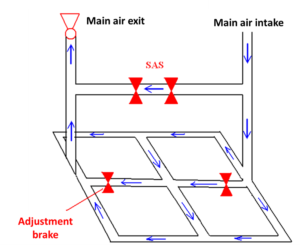

Main airflow is defined as the totality of the air flows that flow through the open lanes of a network of galleries from an access called MAIN AIR INTAKE to an exit called MAIN AIR RETURN.

The main air inlet can be a shaft, a downspout or a horizontal gallery.

The same applies to the main air return.

The SUB’ROCA engineers are at your disposal to assist and advise you in the dimensioning of your ventilation installations. Whether your project concerns a meshed network in an underground mine or a complex digging project in another environment, our teams have the technology to calculate the air requirements and performance necessary to ensure ventilation that complies with the health and safety of personnel.

Principle of operation

Ventilation brakes

A ventilation brake corresponds to a total or partial closure of a gallery to limit the passage of air flow.

There are different types of brakes:

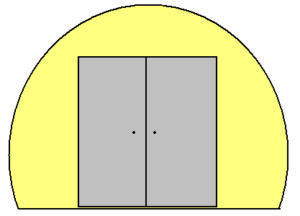

Masonry or wooden brake with doors for the passage of vehicles

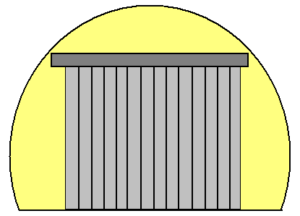

Rubber or plastic bands

Ventilation SAS

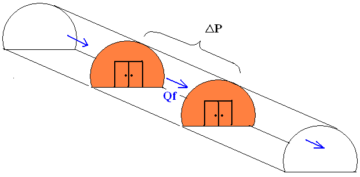

- Consists of two successive closures equipped with doors for the passage of equipment and personnel.

- They are characterised by the pressure difference ∆P existing at their terminals and by the leakage rate Qf.

-

They are installed to separate the air inlet from the return air and thus avoid the short ventilation circuit.

The main fan

Definition

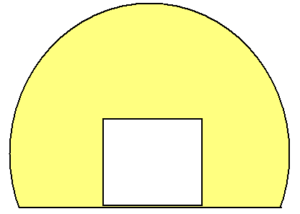

The main ventilation fan is a device designed to convey the air needed for ventilation throughout the mine.

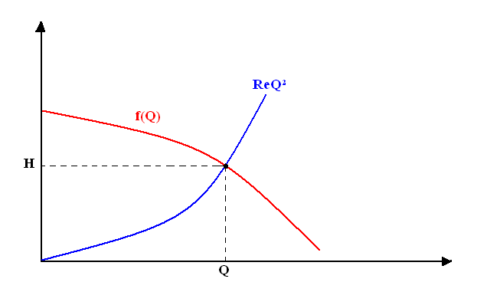

If it has been found that the required air flow Q must overcome a pressure drop ∆P, a fan must be built into the circuit, which will provide the flow with a load increase H=∆P when the same flow Q passes through it.

The basic characteristics of the fan (H and Q) are therefore determined by studying the ventilation system.

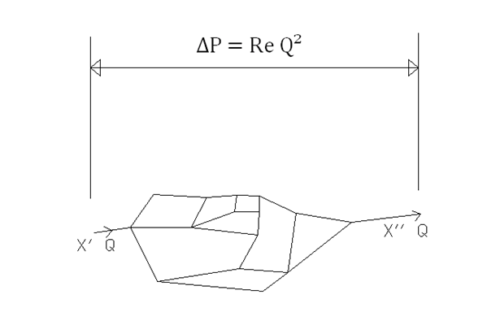

Re is the equivalent resistance of the mine

Figure 1: Ventilation network with a single input and a single output

Ventilation solutions

Our ventilation systems are designed to ensure air renewal in quarries and underground mines. SUB’ROCA offers you a whole range of dedicated axial fans. SUB’ROCA assists you in the dimensioning of your installations.

SUB’ROCA offers ventilation solutions adapted to your work in the basement or « top-down », including the construction of station boxes or shafts.

SUB’ROCA supplies ventilation systems equipped with ducts for tunnels in excavation, up to JetFan (accelerator) for tunnels that are opening. Our equipment can be installed on TBMs.

SUB’ROCA has designed a compact range of high-performance fans in diameters from 250mm to 800mm for ventilating microtunneling excavations and underground networks.