The importance of periodic ventilation and air quality measurements

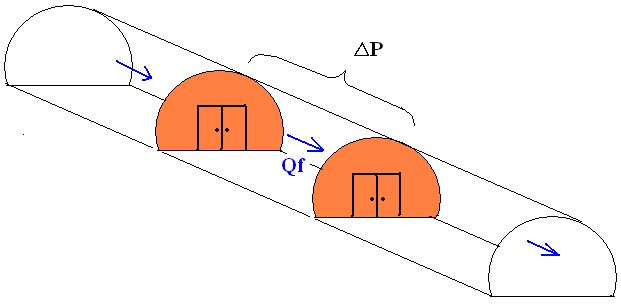

In confined spaces, air quality control is essential. This is possible through knowledge of pollutant emissions, measurements of the concentration of harmful gases in the air and the proper functioning of the ventilation system.

Knowledge of pollutant emissions

The possible pollutants present in the confined environment are identified beforehand in the ventilation study. The most common ones are :

- Gases concerned by the VLEP

- Dust

- VOCs

- Asbestos

To evaluate the emissions of polluting gases from diesel-powered machines, it is recommended that measurements of exhaust gas content be taken every 500 working hours (RGIE).

Measurements of dust levels in the air

Concentration measurements of harmful gases in the air

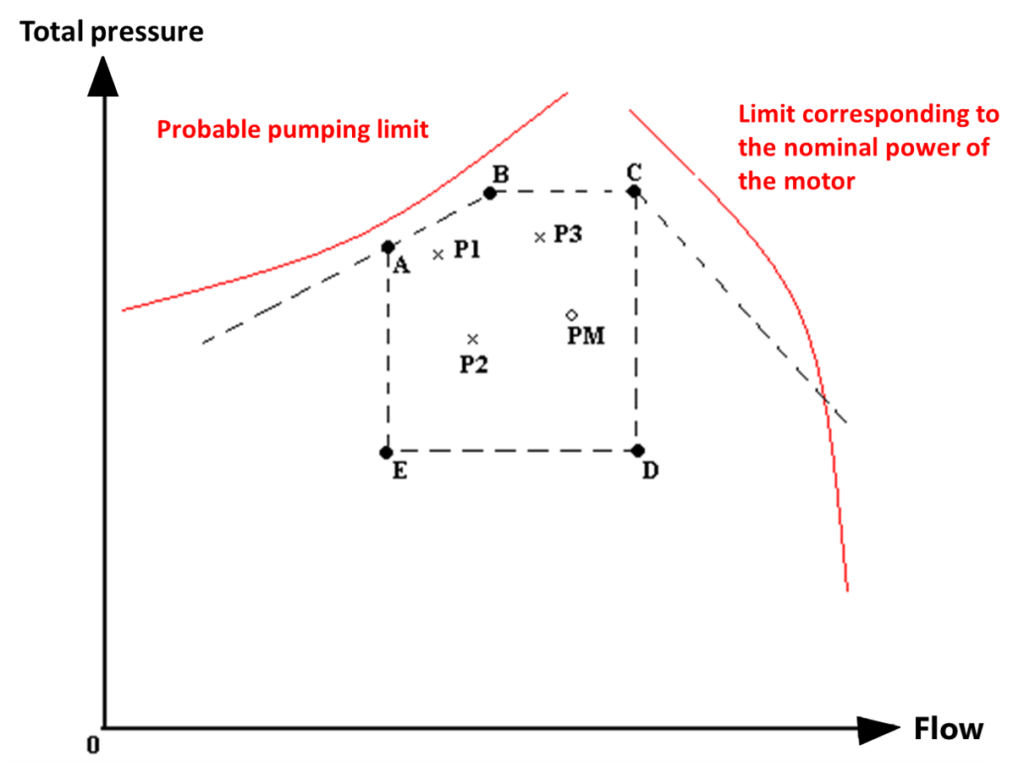

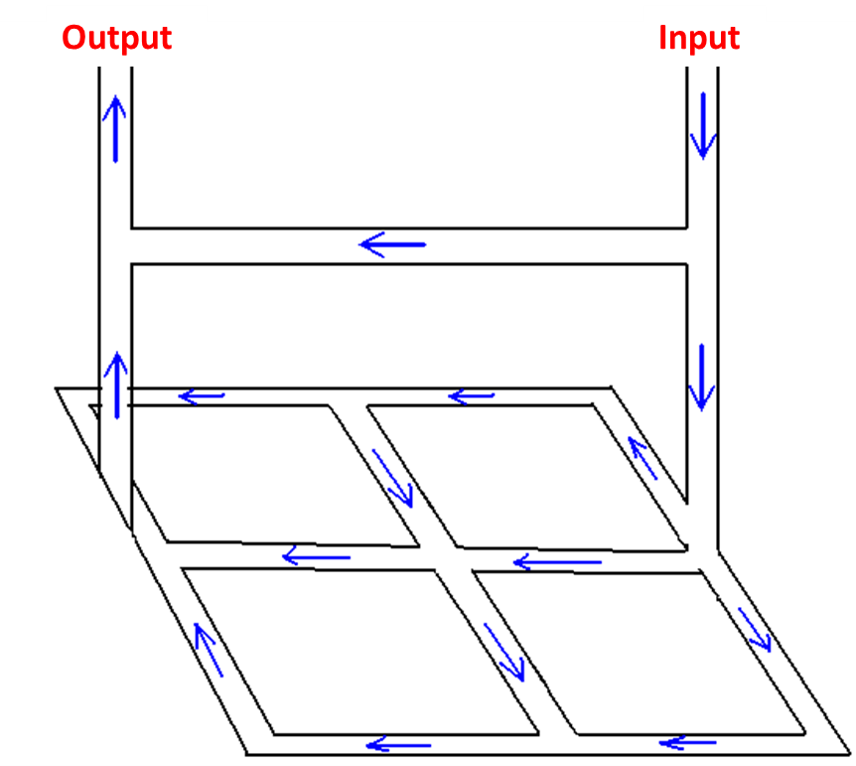

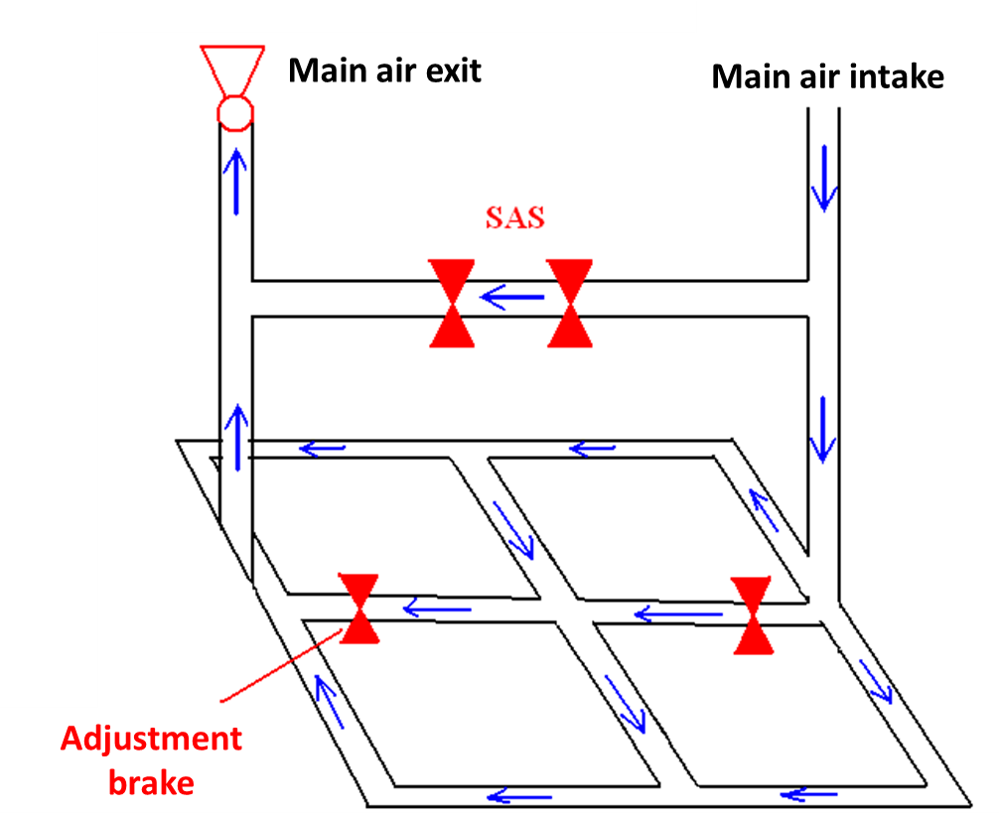

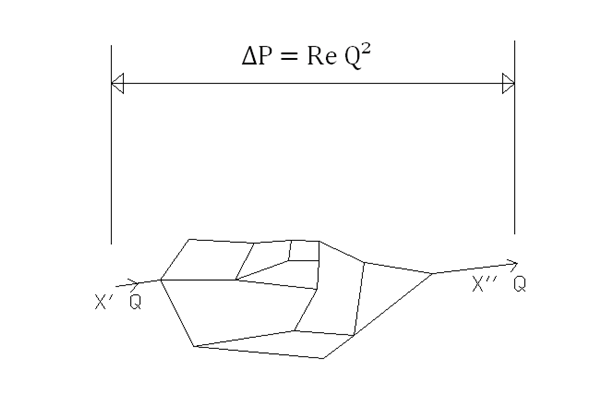

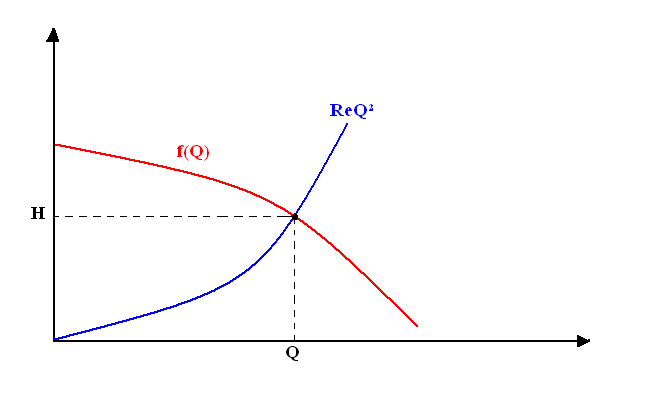

Checking the operation of the ventilation system

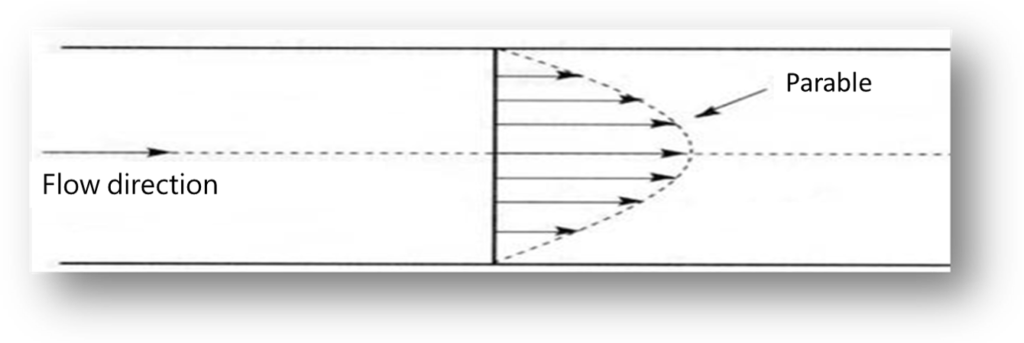

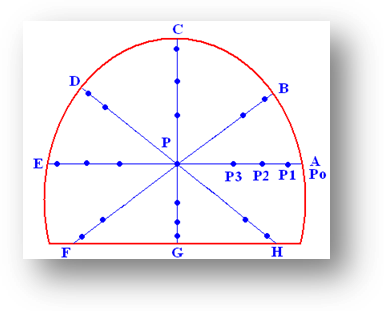

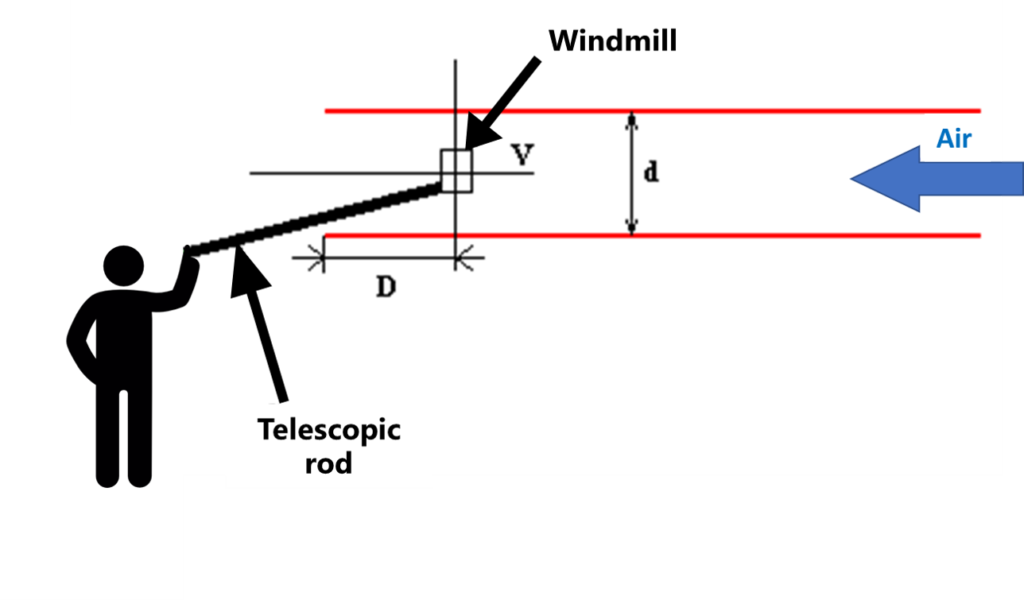

The main measuring devices for checking the ventilation system are the propeller/hot-wire anemometer and the liquid or electronic pressure gauge. Smoke tests should be carried out, if necessary, in order to identify and correct any « dead » zones and to analyze the air flows.

Planning of periodic inspections

- Controls at the operator’s expense

The periodic measurements are carried out at the expense of the operator who appoints an internal person in charge of the subject of the ventilation.

SUB’ ROCA proposes trainings of the personnel to help the operator in this mission.

These periodic measurements are to be carried out at least at the beginning of the building site and each time there is a change of nature of ground, of section, of process of digging, according to the following periodicity (to be adapted to the case by case):

– Gas: daily and instantaneous,

– Dust/fibers: monthly at least (including % free silica),

– Asbestos: weekly at least in potentially asbestos-rich soils or after proven identification.

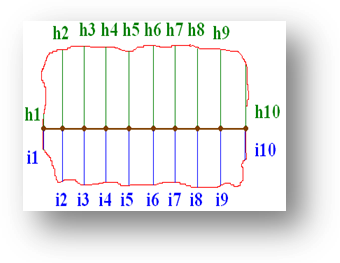

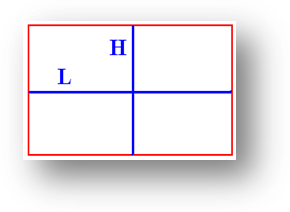

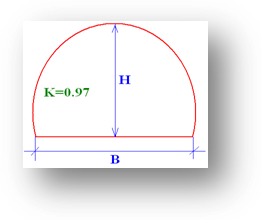

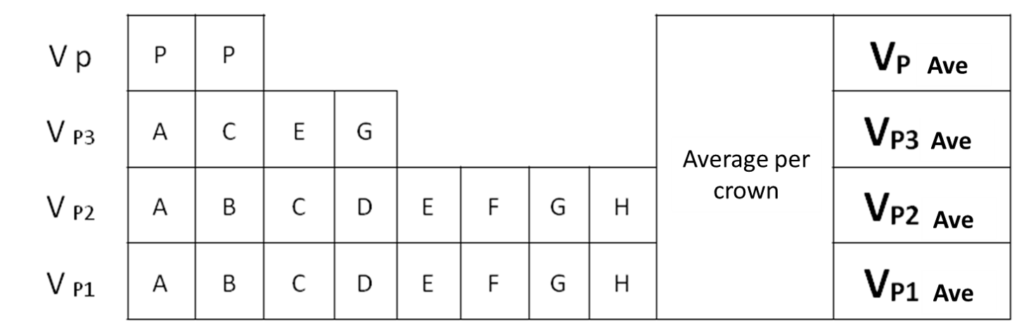

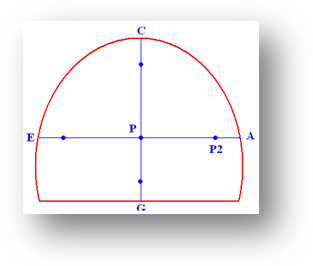

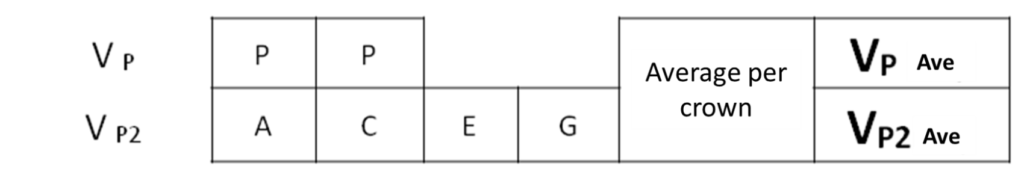

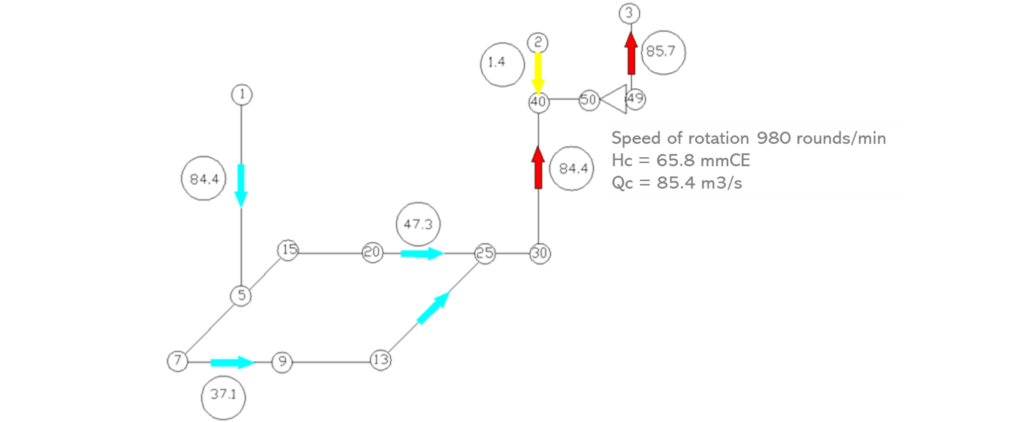

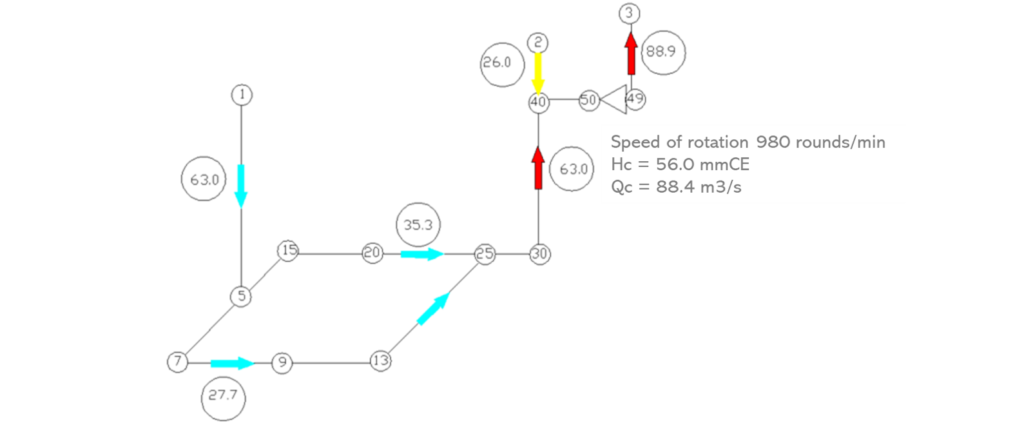

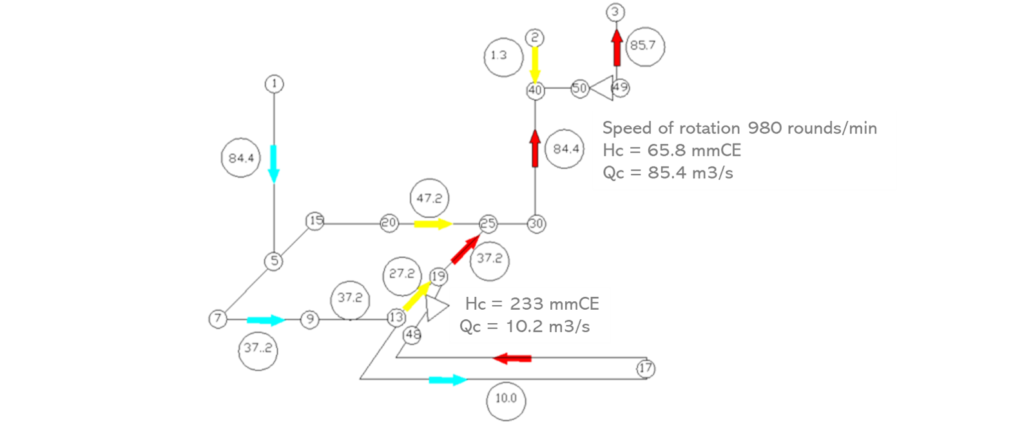

The supply and exhaust air flows, air velocities and duct pressures shall be measured regularly. These measurements should be carried out in particular when there are doubts about the performance of the ventilation, when the installations have been modified or significantly extended. For this purpose, it is recommended to install anemometers, flow meters, manometers on the ventilation network with direct reading.

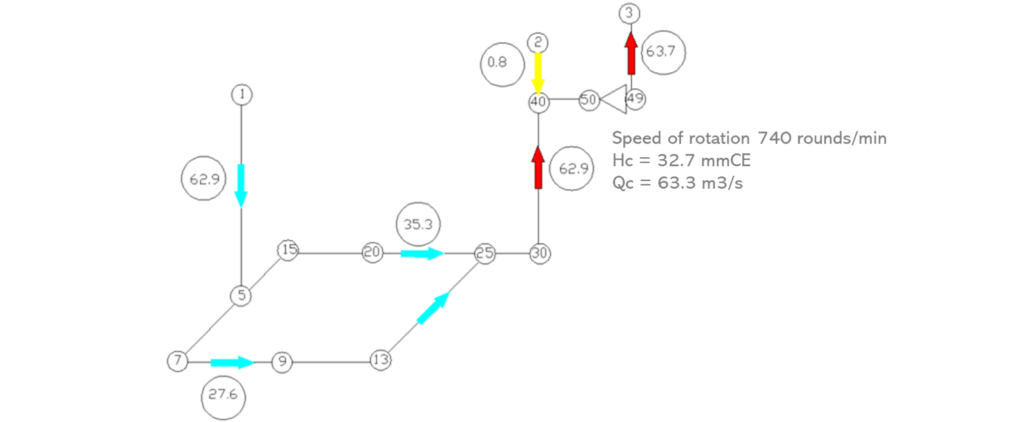

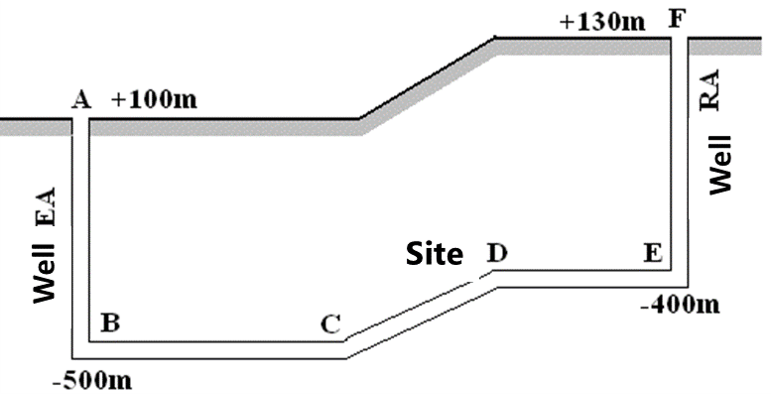

The SUB’ROCA engineers are at your disposal to assist and advise you in the dimensioning of your ventilation installations. Whether your project concerns a meshed network in an underground mine or a complex digging project in another environment, our teams have the technology to calculate the air requirements and performance necessary to ensure ventilation that complies with the health and safety of personnel.